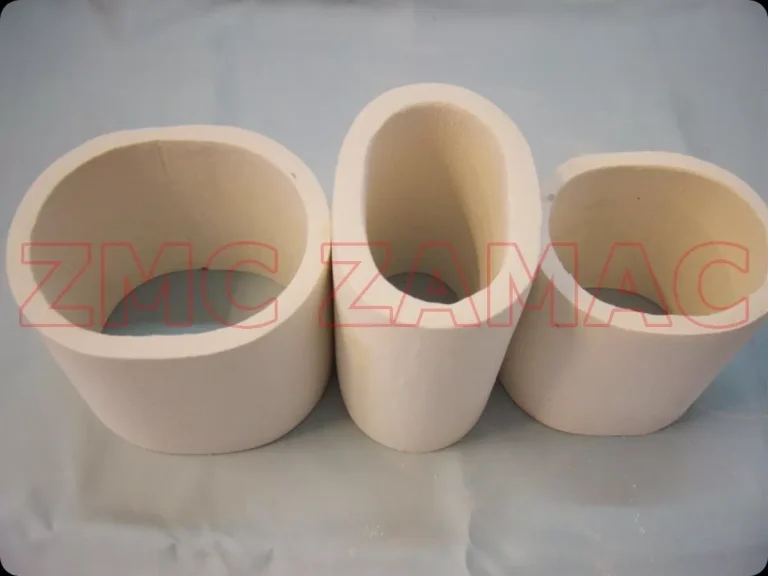

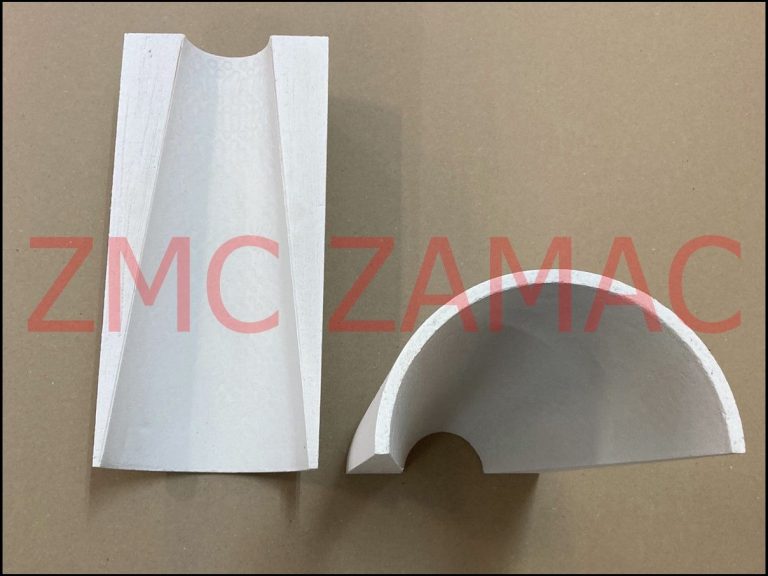

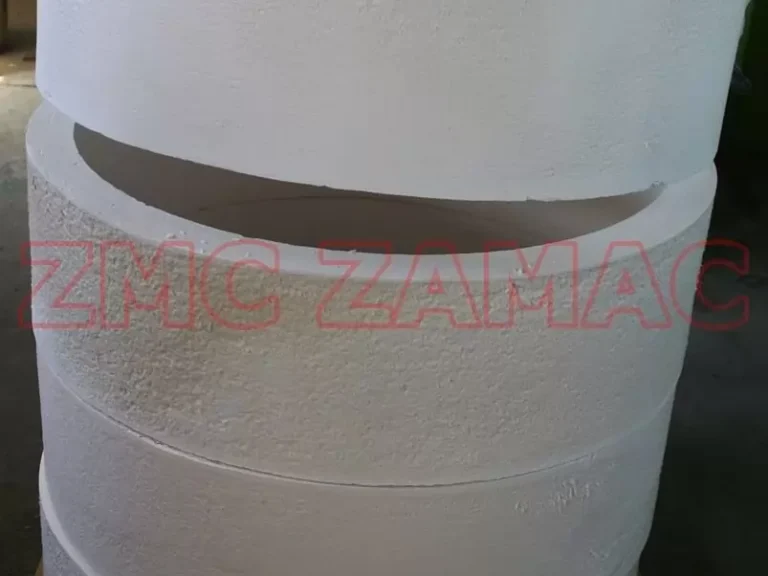

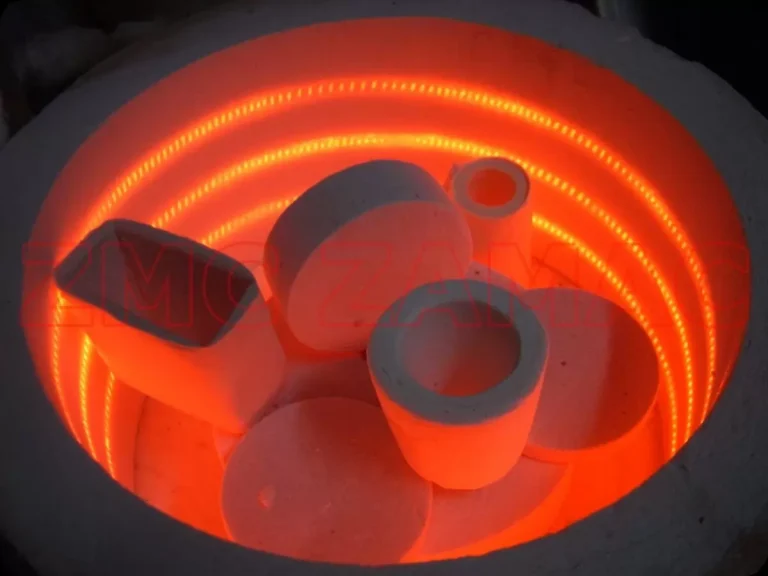

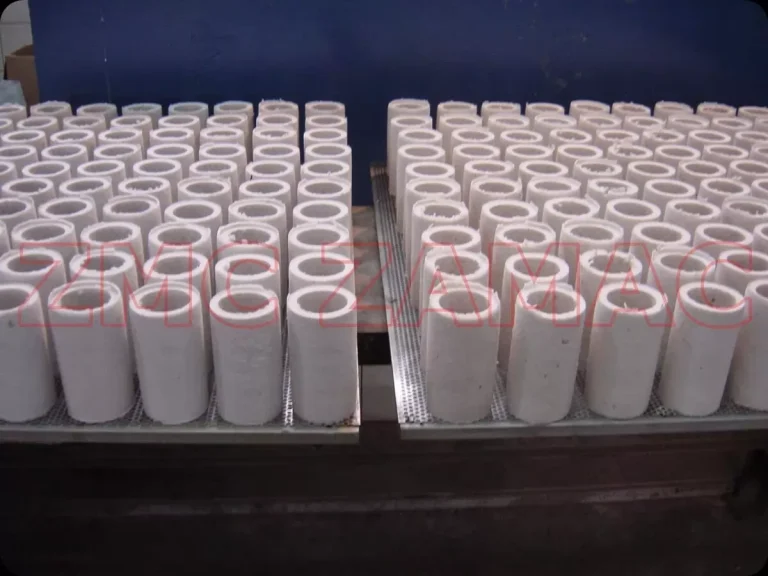

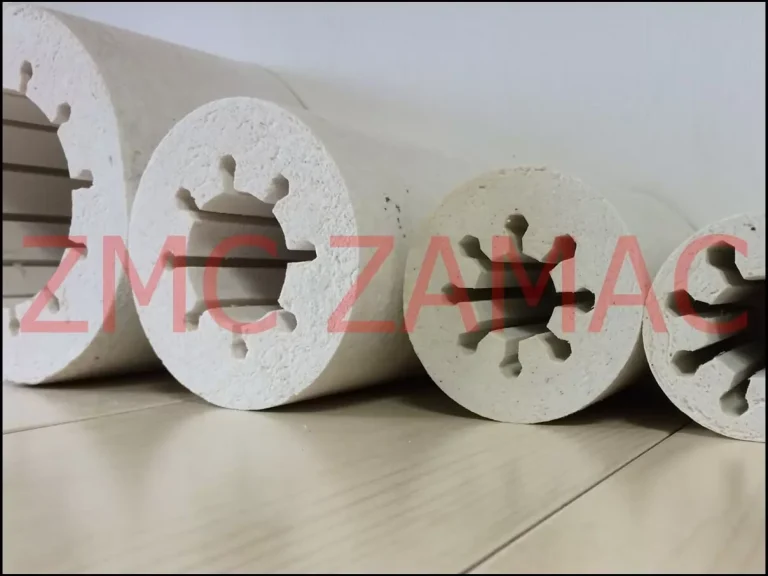

Vacuum formed shapes

Offer

Shapes are manufactured from aqueous suspensions of refractory fibers using the vacuum-forming method, with a precisely selected layout of binders (fire resistance according to arrangements). If necessary, additional protective coating can be applied on these elements. The wall thickness of the most frequently manufactured fittings is 5-50 mm. Due to vacuum-forming they are characterized by good mechanical resistance and low thermal conductivity. They are easily subjected to additional processing. The proper hardness and strength of the fittings ensures resistance to thermal shock and dimensional stability during operation. We are able to manufacture fittings in nearly any geometrical shape.

We offer:

- gating systems

- feeders

- shielding elements, e.g. for thermocouples

- linings

- tap out cones, plugs

- casings

- casting flasks

- hand shank ladles, ladles

- open and closed cylindrical sheaths

- oval sheaths

- rings

- casting sprue with a slot for round filters

- neck down fittings

- etc.

By using our vacuum-formed shapes you will get:

- liquid metal savings

- energy savings

- stable conditions of operation

- increased quality of the casting

- riser solidification time even 35% longer than the casting solidification time

- reduction of shrinkage cavities

- proper course of alloy crystallization

- gas permeability

- reduction of alloy stresses

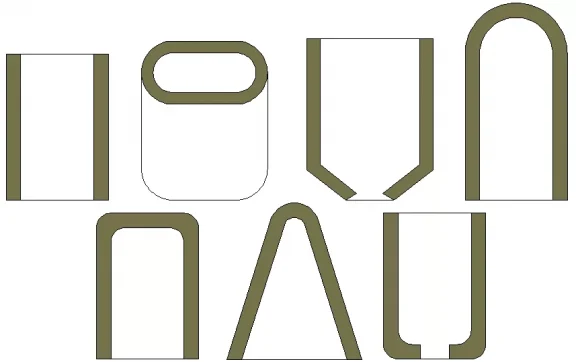

Examples:

The basic types of insulation fittings (i.a. for casting) most frequently manufactured by ZMC Zamac are shown below. Values are given in millimeters. If you require a different fitting, please contact us!

| inner diameter | height |

|---|---|

| 20-25 | 250 |

| 30 | 150, 200, 250, 300 |

| 35 | 250 |

| 40 | 150, 250, 300 |

| 50 | 150, 300, 500 |

| 60 | 150, 250, 300, 600 |

| 70 | 120 |

| 80 | 150, 300 |

| 90 | 60, 400 |

| 95 | 155 |

| 100 | 40, 150, 300, 500 |

| 106 | 400 |

| 110 | 400 |

| 115 | 230 |

| 120 | 40, 150, 200, 600 |

| 125 | 180 |

| inner diameter | height |

|---|---|

| 130 | 250 |

| 135 | 250, 260 |

| 140 | 60, 150, 470 |

| 150 | 40, 150, 180, 500 |

| 160 | 200, 340 |

| 180 | 150, 200, 250 |

| 190 | 500 |

| 200 | 200, 250 |

| 215 | 200 |

| 220 | 350 |

| 230 | 330 |

| 235 | 400 |

| 240 | 150 |

| 250 | 60, 120, 200, 250, 300 |

| 255 | 55 |

| 260 | 190 |

| inner diameter | height |

|---|---|

| 280 | 160, 415 |

| 290 | 160 |

| 300 | 200, 300 |

| 320 | 230, 350 |

| 360 | 230 |

| 400 | 250, 300 |

| 450 | 250 |

| 460 | 150, 210 |

| 475 | 300 |

| 600 | 200 |

| 630 | 200 |

| 760 | 200, 250 |

| 800 | 200 |

| 870 | 250 |

| outer width | inner lenght | height |

|---|---|---|

| 40 | 80 | 150, 300 |

| 60 | 100, 140 | 150, 300, 600 |

| 70 | 140 | 230 |

| 80 | 100, 125, 160 | 120, 150, 280 |

| 100 | 120, 200 | 120, 150, 200, 300 |

| 120 | 140, 240 | 200 |

| inner diameter | inner diameter neckdown | height |

|---|---|---|

| 50 | 25 | 100, 150 |

| 60 | 45 | 300 |

| 78 | 38 | 100, 150, 250 |

| 85 | 45 | 100 |

| 94 | 48 | 100 |

| 118 | 60 | 150 |

| 147 | 70 | 195 |

| inner diameter down | height | R |

|---|---|---|

| 50 | 76 | 20 |

| 102 | 133 | 43 |

| 80 | 130 | 35 |

| 120 | 192 | 53 |

| 151 | 235 | 65 |

| 200 | 310 | 90 |

| inner width | inner lenght | height |

|---|---|---|

| 50 | 100 | 85 |

| 30 | 80 | 70, 150 |

| 40 | 80Z | 150, 260 |

| inner width | inner lenght | height |

|---|---|---|

| 53 | 100 | 10 |

| 71 | 157 | 6 |

| 80 | 152 | 16 |

| 82 | 143 | 17 |

| 83 | 187 | 6 |

| 102 | 242 | 6 |

| inner diameter | height |

|---|---|

| C40 | 150 |

| C50 | 70 |

| C50 | 165 |

| C50 | 250 |

| C60 | 150 |

| C60 | 200 |

| C60 | 250 |

| 110 | 150 |

| 140 | 230 |

| 150 | 270 |

| 160 | 100 |

| 250 | 250 |