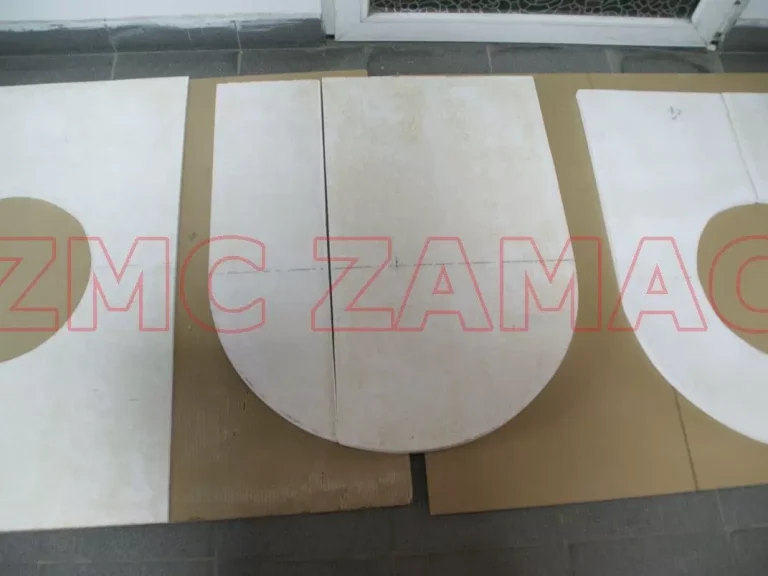

Insulating boards

Offer

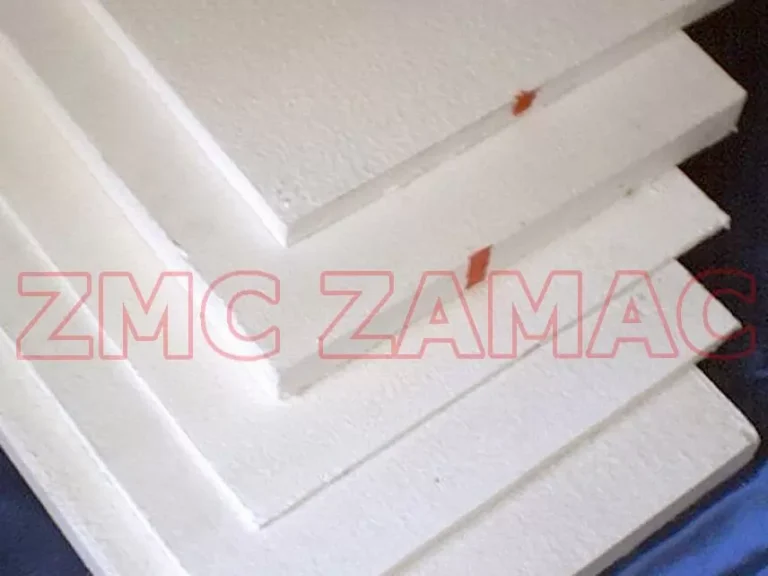

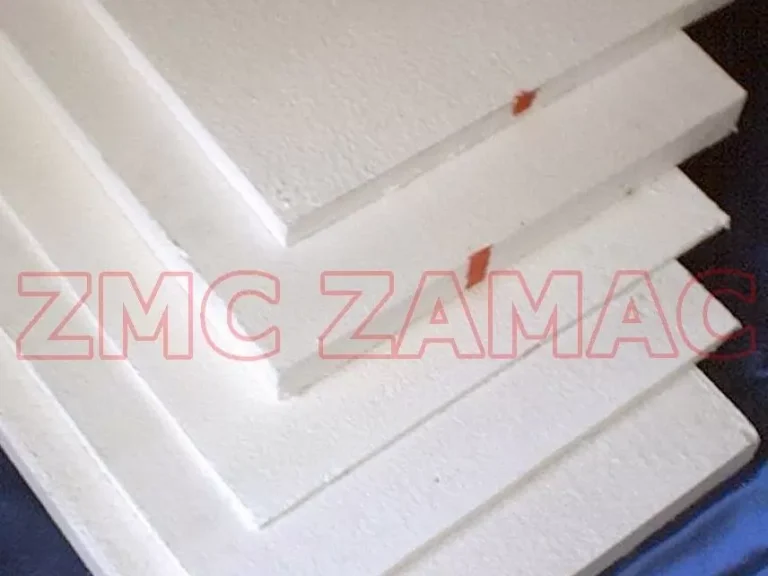

The insulation boards are manufactured from aqueous suspensions of refractory fibers using the vacuum-forming method. The precisely selected layout of binders allows for the use of a minimal amount of (non-toxic) organic elements. They are removed during the first annealing, from the temperature of approximately 250 °C. As a result the board becomes completely odorless and returns to the white color. In terms of the classification temperature, we manufacture two types of boards: 1260 °C and 1430 °C.

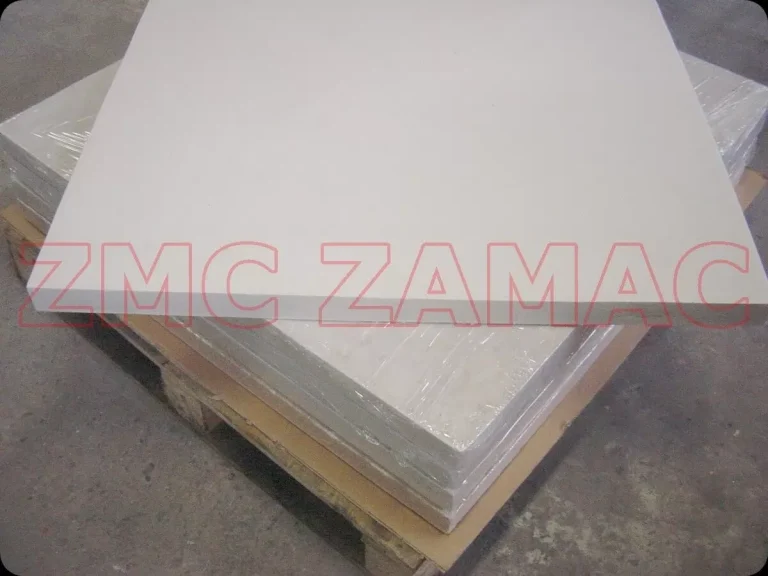

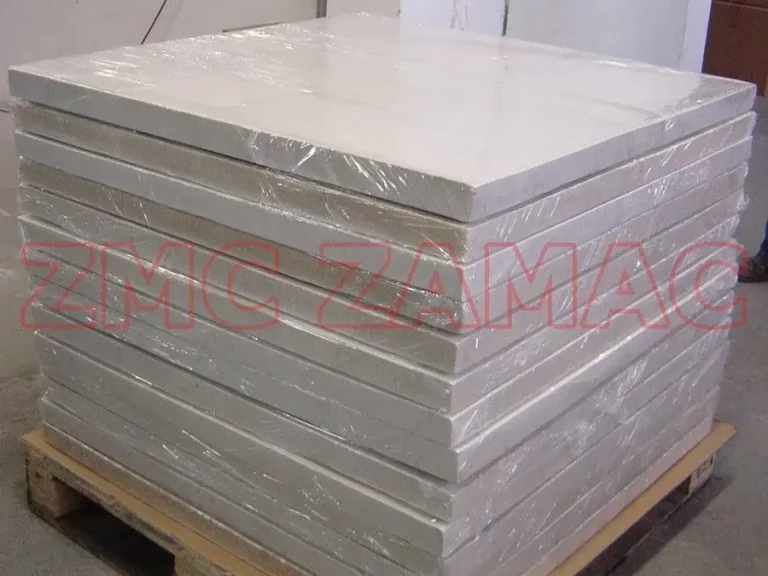

With concern for our products, shipping of insulation boards is performed only on pallets.

Characteristics:

- excellent homogeneity

- good mechanical resistance

- resistant to most chemicals

- excellent volume stabilization

- low apparent density

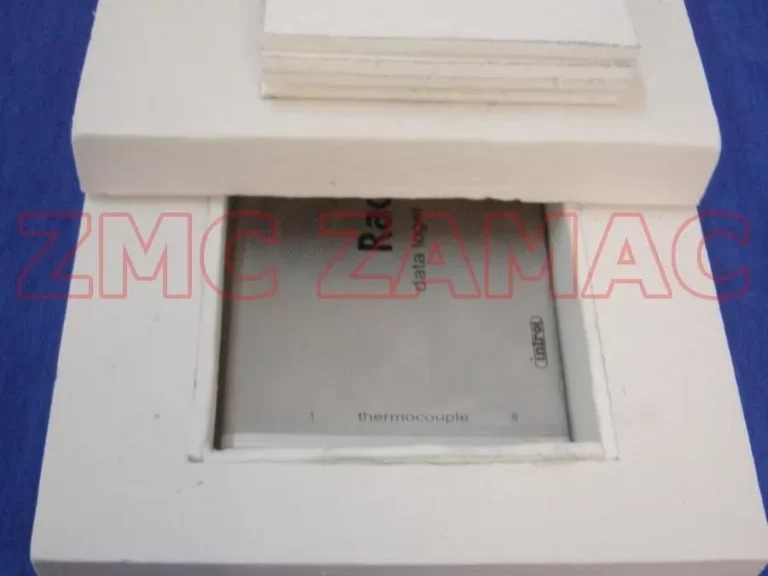

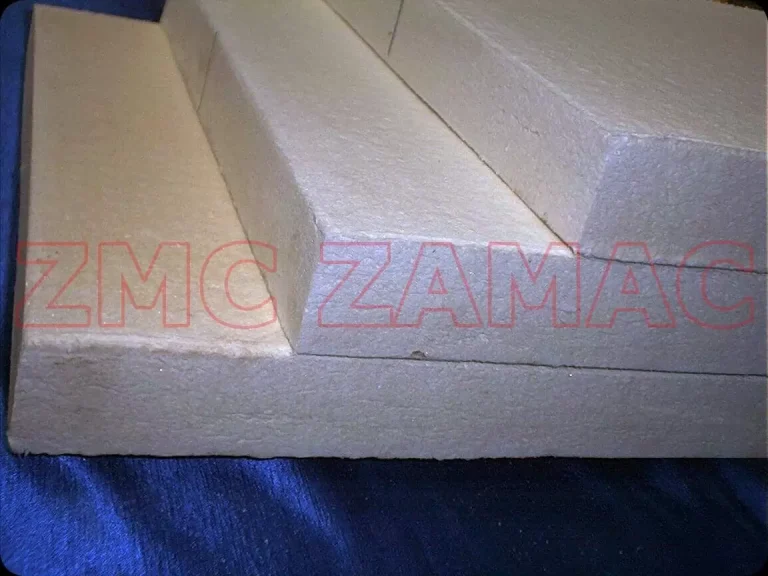

- easy mechanical processing (cutting, drilling, milling)

- stability in high temperatures

- resistant to sudden temperature changes

- can be used in direct contact with flames

- low heat accumulation ratio

Application:

- lining of furnace vaults and walls

- lining of combustion chambers in boilers

- lining of boilers and water heaters

- insulation of smelters and glass furnaces

- dilatation, fire screens

- general purpose thermal barrier

- insulation of ceramic kiln cars

- lining of heaters

- repair and modernization of older types of furnaces

- insulation of channels, ducts

- insulation of the working part of hard ceramics, such as refractory bricks

- thermal insulation in various branches of industry

| PT-2 | PT-3 | |

|---|---|---|

| Classification temperature | 1260°C | 1430°C |

| Density | 400 kg/m3 | 400 kg/m3 |

| short-term | 1160°C | 1350°C |

| long-term | 1320°C | 1500°C |

| Linear shrinkage % | max. 3% | max. 3% |

| Compressive strength [N/mm2] | +0,15 | +0,15 |

| Thermal conductivity(W/m*K): | ||

|

0,11 | 0,10 |

|

0,14 | 1,13 |

|

0,16 | 0,16 |

|

0,19 | 0,19 |

| Chemical analysis of the fibers

: |

||

|

min. 47% | min. 52% |

|

max. 54% | max. 46% |

|

max. 0,3% | max. 0,2% |

|

max. 0,5% | max. 0,5% |

| Lenght | Widgth | Height |

|---|---|---|

| 1000 mm | 1000 mm | 50 mm |

| 1000 mm | 500 mm | 50 mm |

| 1000 mm | 500 mm | 40 mm |

| 1000 mm | 500 mm | 30 mm |

| 1000 mm | 500 mm | 20 mm |